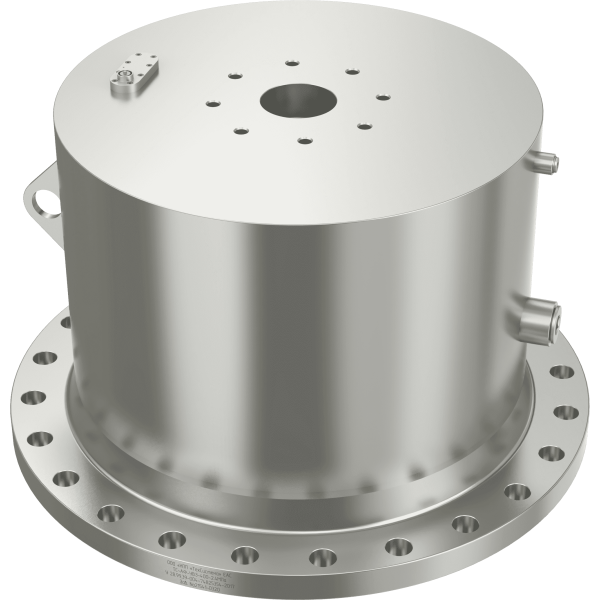

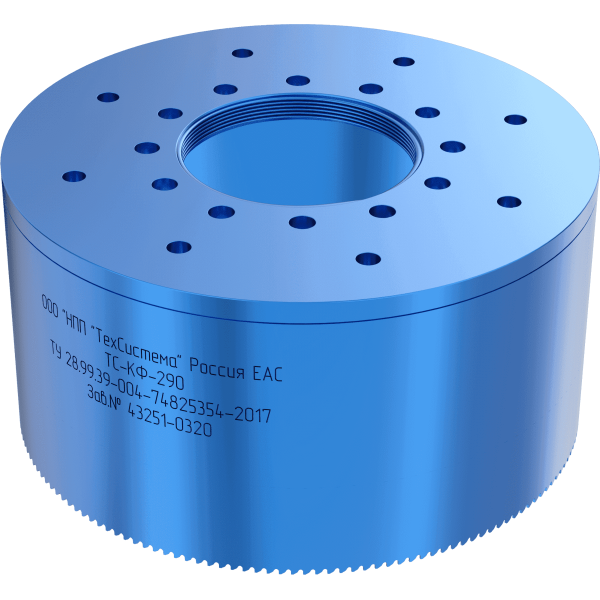

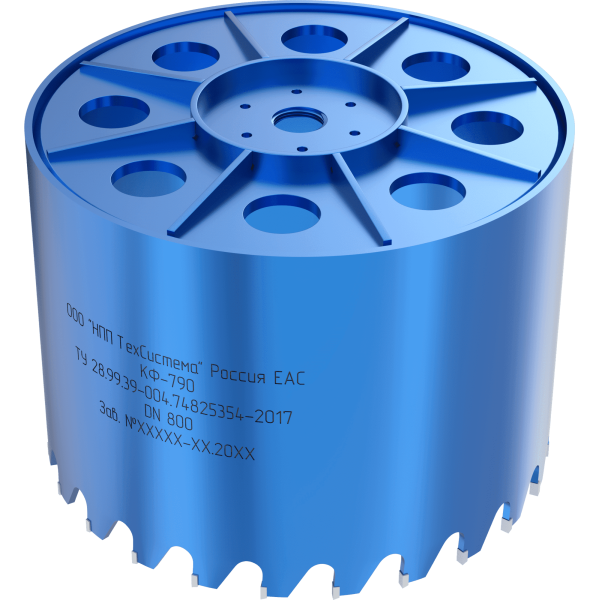

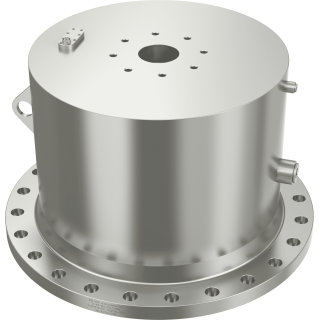

Drilling machines DM 300-800 are equipped with flange adapters, allowing them to be mounted on gate valves and flanged shut-off valves.

Structurally, all DM 300-800 drilling machines are made according to a single scheme, with a three-column housing, a central shaft, a side feed screw and controls located at the bottom base. This arrangement makes it possible to eliminate one of the major disadvantages of similar drilling machines – top control layout, which forces to apply the relevant safety standards for operators working at heights.

The working feed is carried out manually, the accelerated movement of the cutter up / down – by the feed hydraulic motor. The value of the vertical stroke of the shaft is controlled by the counter readings and is duplicated by a vertical ruler located on one of the stands of the drilling machine.

Drilling machines DM 300-800 can be equipped with video surveillance points connected to the video surveillance and control device and allowing to visually control the process of tapping into the pipeline in real time.

The shaft rotation drive is equipped with a stepless hydraulic flow regulator that allows you to select the most optimal speed for specific drilling conditions.

The hydraulic motors of the DM 300-800 drilling machines are powered from a hydraulic oil station with a working pressure of 14.0 MPa and a flow rate of 30 l / min.